[ Zingana ]

Wood property:

Air-dry density is about 0.80 g/cm³, with high harness and straight texture. Its structure is fine and even. Suitable for carving and process by hammer. It has good adhesiveness.

【 Application 】:

high-end suite furniture, decorative moulding, floor, musical instrument, shipbuilding and carving

【 Usual application effect 】:

Colored transparent full-closed application and colored transparent open application.

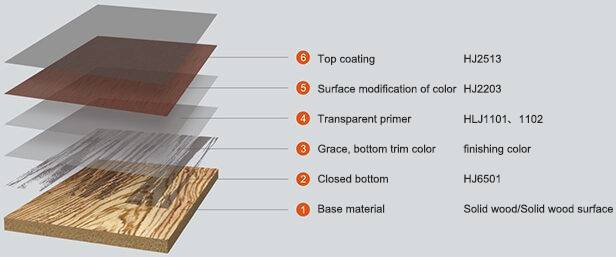

【 Process name 】:

Substrate dyeing full-closed application process

【 Process features 】:

The coating film is transparent with good fullness and layering. The application efficiency is high, which can effectively reduce sinking risk.

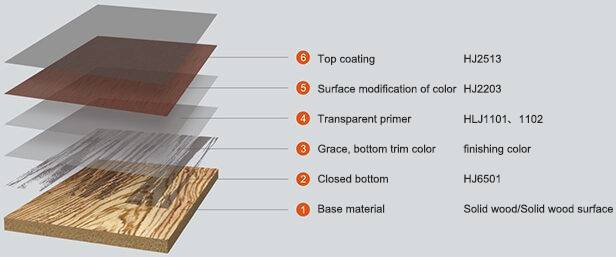

【 Paint breakdown 】:

[ MDF ]

Wood property:

Density: 0.50~0.88 g/cm³, even structure and density, with good stability and little transformation. It is easy to be carved or planed into furniture parts of all kinds of sections and shapes. When it is made into special edge, it can be treated with paint without any edge sealing needed.

【 Application 】:

cupboard, wooden door, furniture, display props, soundbox, TV case, musical instrument, ships, sports equipment, etc.

【 Usual application effect 】:

matte real-color application, bright real-color application.

【 Process name 】:

real-color closed (matte) process

【 Process features 】:

little odor in application, good fullness, anti-yellow and transformation with good gloss retention performance.

【 Paint breakdown 】:

[ Ash ]

Wood property:

Air-dry density 0.60~0.72 g/cm³, the wood is usually straight and flat with even texture. The processing performance is good and can be fixed with nails, bolts and glue. Good surface effects can be obtained after dying and polishing.

【 Application 】:

Wooden door, American furniture, floor, high-class hat and coat stand, fine wood work, sports equipment, tools handle, etc.

【 Usual application effect 】:

Colored transparent full-closed application and archaizing application.

【 Process name 】:

Semi-transparent full-closed application process

【 Process features 】:

Obvious semi-transparent effect, looming mystery and rich layers

【 Paint breakdown 】:

[ Fraxinus Mandshurica ]

Wood property:

Air-dry density 0.81~0.98g/cm³, coarse texture. The wood is tough, wet-resistant, hard to dry and easy to bend; easy to have transformation with large dry shrinkage performance; processing performance is good, being able to be fixed with nails, bolts or glue; the section is smooth with good paint and glueability. Good surface effect can be made after dying and polishing.

【 Application 】:

Wooden door, cupboard, crafts, display props, furniture, musical instrument, spots equipment, cars and ships.

【 Usual application effect 】:

Colored transparent full-closed application and archaizing application.

【 Process name 】:

Transparent colored shining application process

【 Process features 】:

good sense of fullness and layer and easy application

【 Paint breakdown 】:

[ Red Oak ]

Wood property:

Air-dry density 0.85~0.9 g/cm³, coarse texture, high density, dry slow and is easy to crack and bend; large-shrinkage rate and property easily changed. The machining property is not very good and not suitable for the use of nails or bolt. Drilling is recommended.

【 Application 】:

Wooden door, furniture, floor, cupboard, office furniture, vanity, etc.

【 Usual application effect 】:

Colored transparent full-closed application, colored transparent open application, real color open application and archaizing application.

【 Process name 】:

Transparent substrate dyeing closed application process

【 Process features 】:

good sense of fullness and layer and easy application

【 Paint breakdown 】:

[ Black Walnut ]

Wood property:

Air-dry density 0.61~0.78 g/cm³. It is hard, fine and even, not easy to crack, bacterial, termite and corrosion resistant; with medium bending and compression resistance. The toughness is bad, but with good hot-press forming ability. The black walnut is suitable for craft work and machinery processing like nailing, drilling and gluing. The paint and pigment is long lasting and polished to special effect.

【 Application 】:

High-end car interior decoration, furniture, cupboard, vanity, floor, structural plate of musical instrument, gun stock and high-class crafts.

【 Usual application effect 】:

Colored transparent full-closed application, colored transparent open application and archaizing application.

【 Process name 】:

Base surface full-closed application process

【 Process features 】:

fully filled, natural color, simple and nature effect, preventing collapse

【 Paint breakdown 】:

[ Elm ]

Wood property:

Air-dry density is about 0.68 g/cm³, with straight and coarse texture, clear pattern and smooth plane surface. The wood is tough with medium hardness and strength, difficult to dry, easily crack and warp. After drying, shaping, carving, grinding and painting, it can be made to be a fine carved lacquer artwork.

【 Application 】:

High-end furniture, cupboard, carved lacquer artwork and altar table in temple.

【 Usual application effect 】:

Colored transparent full-closed application and archaizing application.

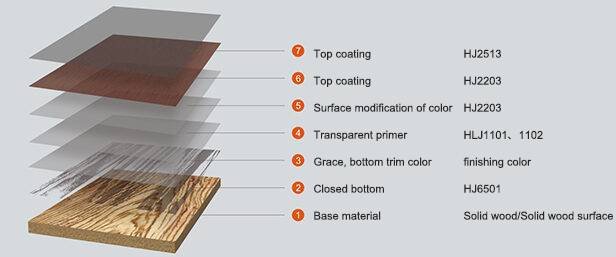

【 Process name 】:

Multi-layer full-closed application process

【 Process features 】:

Vivid and natural color. Excellent breathability. Strong layering sense with good effect.

【 Paint breakdown 】:

[ Teak ]

Wood property:

Glossy, air-dry density 0.58~0.67 g/cm³. Oily shining, the texture and color is even. The wood property is table with small shrinkage coefficient with the minimal deformation coefficient among woods. Good adhesiveness and painting and waxing performance.

【 Application 】:

High-end furniture, floor, interior and exterior decoration, shipbuilding, outdoor buildings and bridge.

【 Usual application effect 】:

Colored transparent full-closed application, colored transparent open application and natural color transparent open application.

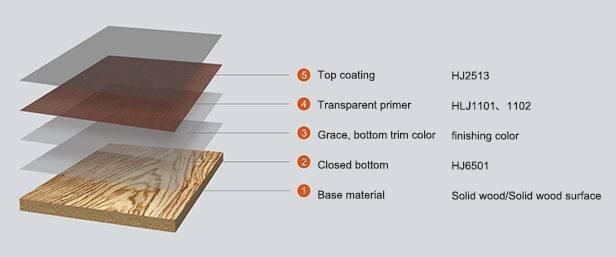

【 Process name 】:

Wax oil open application process

【 Process features 】:

Natural texture, environmental-friendly and easy application

【 Paint breakdown 】:

[ Calophyllum ]

Wood property:

Air-dry density: 0.60~0.74 g/cm³. It is medium in weight and strength. The structure is coarse with interlocking texture; easy to have warping and raw edge, with large shrinkage; its surface is easily torn. Suitable for planning and sawing, not suitable for process with hammer. It has good adhesiveness and polishing performance.

【 Application 】:

high-end suite furniture, decorative moulding, floor, musical instrument, shipbuilding and carving

【 Usual application effect 】:

Colored transparent full-closed application and colored transparent open application.

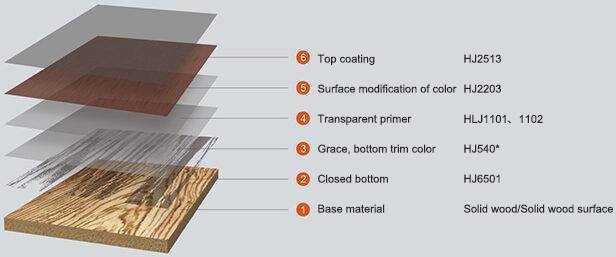

【 Process name 】:

Substrate dyeing full-closed application process

【 Process features 】:

The coating film is transparent with good fullness and layering. The application efficiency is high, which can effectively reduce sinking risk.

【 Paint breakdown 】: